Description

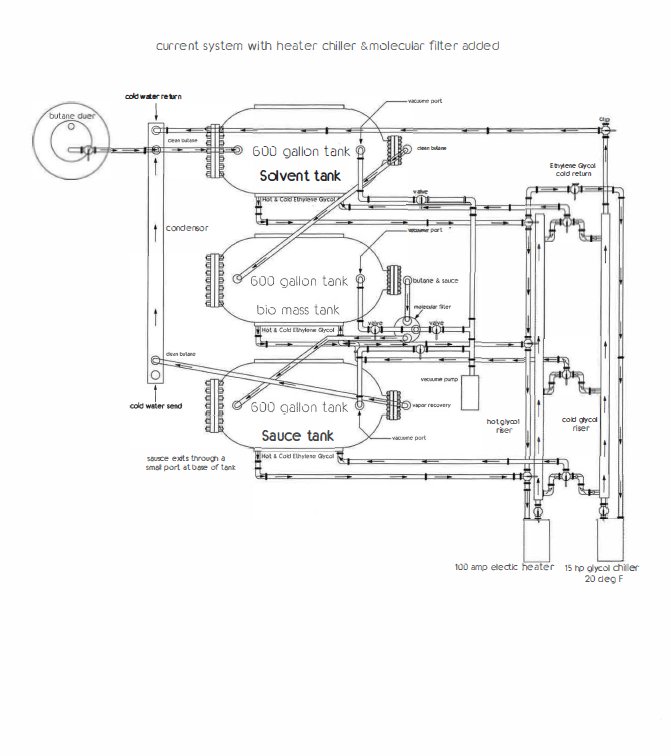

Our botanical herbal oil extractor system is designed to effectively extract essential oils and

extracts from herbal materials using pressurized light-hydrocarbon solvents. This system is a

closed-loop type specifically designed for the use of LPG (butane) as the extraction solvent.

LPG solvent avoids the need to use extreme temperatures or pressures in the extraction process

and can be completely removed from the extracted solutes with basic evaporation techniques.

Design

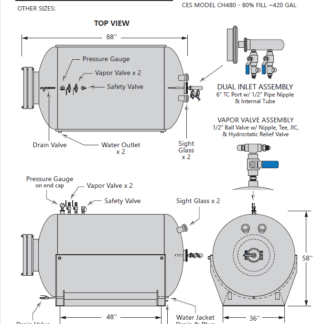

Certified: The system pressure vessels are manufactured and marked ASME certified for MAWP of

250psi @ 100°F, designed for LPG use. The accessories and hoses are rated LPG-350-PSI to meet

NFPA-58 regulations for LPG installations. ASME: American Society of Mechanical Engineers; ref.

BPVC Section VIII – Rules for Construction of Pressure Vessels Division 1 (BPVC-VIII-1 – 2013). NFPA:

National Fire Protection Association; ref. Liquefied Petroleum Gas Code (NFPA-58 – 2017).

Cleanable: The system vessels and accessories are manufactured of food-grade 304/316 stainless

steel and are electro-polished for producing pure extracts and ease of cleaning after extraction.

Rounded edges, seamless tubing and polished welds help ensure sanitation standards can be met.

Many tank models have bottom drains for easier solvent wash-down and sterilization.

Modular: The extractor design allows many variations on the basic extraction process. Available

connections, valves and accessories permit a variety of process steps to be used or modified. A wide

range of temperatures, pressures and dwell times are possible for different process steps. An enthusiast

can certainly develop one’s very own special process.

Safety

Flammable: LPG (liquefied petroleum gas: butane is extremely flammable and can create an explosive

atmosphere when mixed with air. LPG becomes explosive at as little as 2% content in air. Keep away

from open flames, heat, sparks, and hot surfaces – no smoking.

Leaks: Although this extractor system has closed-loop type design intended to operate without

leakage of the LPG, and to recover the solvent after extraction for reuse, some release of LPG must be

expected and planned for. The herbal materials may retain some LPG depending on how thoroughly

vaporized after extraction, which may be released upon removal from the unit. Some process steps may

release a small amount of LPG, as when purging air from a hose. One must plan for the possibility of an

operating error or improper seal allowing an outright LPG leak. Equipment must be configured with

shutoff valves on every nozzle of every pressure vessel to permit quick isolation of any component.

Heavier-than-air: LPG is heavier-than-air and will sink down to the floor or ground and collect in low

areas, corners, basements and crawl-spaces. The basic rule is to never allow an accumulation of LPG

at even one-fourth the explosive mix, or less than ½% – that is very little. You cannot smell LPG if not

odorized.

Ventilation: The key to safety when extracting using LPG is proper ventilation. Where permitted,

operate the extractor system in an open area away from walls or low spots and away from any sources of

ignition. Where necessary to operate indoors, a properly designed hazardous environment facility

must be used, with suitable exhaust ventilation for LPG, explosive atmosphere electrical and fire safety

equipment, and proper storage of the LPG supply.

EXTRACTOR SYSTEM OVERVIEW

CERTIFIED SYSTEMS

2gloves and eye or face

protection are always necessary. Clothing should cover all flesh and be rated FR for Flame-Resistant

(ref NFPA-2113). Besides a flash fire hazard, compressed LPG upon release is very cold and can cause

immediate frostbite of any exposed flesh. In addition to an explosion hazard, concentrated LPG can

displace air in a confined space and cause asphyxiation without warning. Indoor facilities should and

may be required to have LPG gas detector devices to warn of a leak or developing hazard.

Equipment: Electrical equipment within the hazardous area should be rated explosion-proof or

intrinsically-safe and be grounded to earth. Exhaust ducting should be rated conductive and be

grounded. Exhaust fans should be rated for LPG and be grounded. The recovery pump should be rated

suitable for LPG and set-up not to exceed the pressure rating of the recovery tank. The vacuum pump

needs to be suitable for LPG and vented outdoors unless only venting air or proceeded by a separator

or trap device to remove the LPG before the pump. Firefighting equipment should be ready; at least a

portable extinguisher and perhaps a sprinkler or extinguishing system (consult the local fire department).

Safety Valves: Pressure vessels come with pressure relief safety valves, to prevent an excessive gas

pressure build-up. They are set to the vessel pressure rating and must not be removed. Accessories,

pipes and hoses exposed to liquid LPG must be equipped with a hydrostatic relief valve between any

two shutoff valves, to release pressure from liquid expansion due to warming. They are set to 450 psi

and must not be removed. A separate new hose or pipe run needs to include a hydrostatic relief valve.

Regulations: The facility must comply with all state and local regulations and codes, which often refer to

national standards like NFPA and federal regulations like OSHA (consult the local building and fire

departments). For reference, an LPG solvent extraction area within a facility is classified a Class 1,

Division 1, Group D explosive atmosphere hazardous area (which may also apply to other areas).

Standards: The design standards for equipment and facilities, and the standard procedures for LPG

storage and operating equipment, have been developed to minimize dangers and improve safety. It is

critical that these standards and procedures are stringently followed to minimize risks and accidents.

Please give safety it’s proper due, so you can enjoy the fruits of your labors. Always, SAFETY FIRST.

PPE (Personal Protective Equipment) is vital for operator safety. Proper

Reviews

There are no reviews yet.